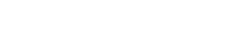

1C. Open garage with passive IR detectors

Dimmable HF operating devices, ‘Dynamic lighting control’

| Premises

If the garage is on several levels or designed as a multi-storey with openings to the outside, passive IR technology must be used. This also makes it possible to subdivide large garages into different areas to avoid lighting unused areas. This application shows subdivision into four different areas controlled separately. At the entrance vehicles turn left or right and thereby light up the side and area in question. A disadvantage of IR detectors is that high vehicles may conceal the detector. Light sources The fittings in this garage have dimmable HF operating devices with analogue control (1 – 10 V). Positioning of detectors In this example the lenses have been replaced by Nos. 41 and 45. The range of these lenses is 41 and 58 m respectively and two long-distance fields of up to 83 m. The opening angle is 90°. This means they must be positioned in corners and in intercepting locations in front of entrances so that passage will be at 90° to the fields of detection. The example provides good insight into how to optimise positioning of the detectors. Unfortunately one all too often sees detectors mounted flat on the wall and aimed at doors and entrances, with the consequence that detection is considerably impaired. Installation of the detectors should be using the simplest possible cable, Type EKKX 1 x 4 x 0.25 mm2. All detectors should be connected in parallel with the rectifier EXE-2000, even if they form part of different areas.

|

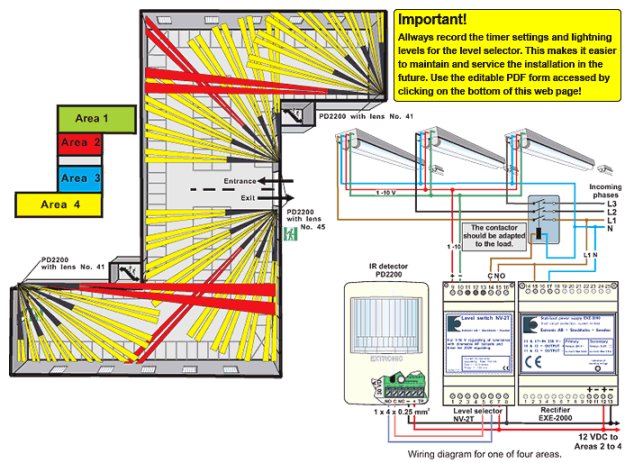

Regarding adjustment of the IR detectors one is referred to the manual enclosed with the detector. NV-2T level selector is also available with DSI control (NV-2TDSI). Control system With new buildings or renovations where there is the option of selecting fittings with dimmable operating devices, on the basis of proven experience and the state of technology it is now a serious mistake not to introduce installation in accordance with the Dynamic Lighting Control principle. The technology can be used both with acoustic control and with control using IR detectors. The wiring diagram for Dynamic Lighting Control using IR detectors is shown below. The most important advantages attained using Dynamic Control are as follows:

With knowledge of current technology, it is bad practice not to utilise Dynamic Control in frequently used premises. Information for current budget

|

||||||||||||||||||||||||

|

|||||||||||||||||||||||||

| Dynamic lighting control with NV-2T in garage The yellow area shows the energy consumption with lighting control according to the light source manufacturer’s recommendations. The green area shows the energy consumption with lighting control installed. |

|||||||||||||||||||||||||

|

|||||||||||||||||||||||||