6A. Warehouse passages with passive IR detectors

Dimmable HF operating devices and ‘Dynamic lighting control’

| The premises

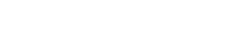

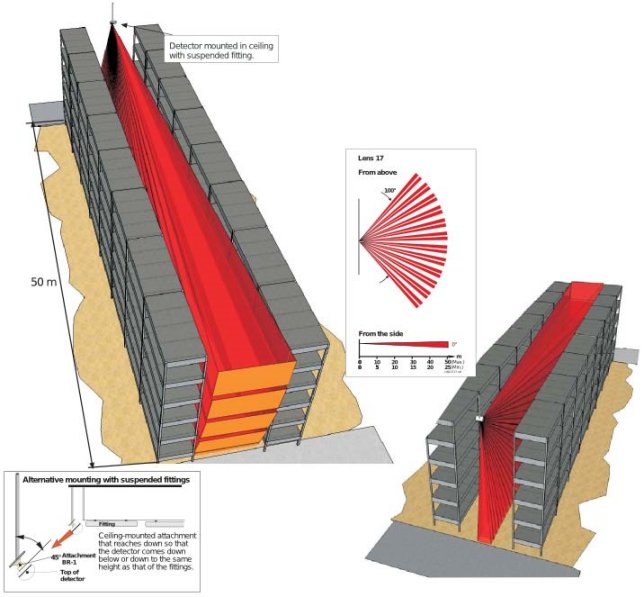

Open warehouse passages with stocks or pallet shelving. Light sources The fittings in this warehouse have dimmable HF operating devices with analogue control (1 – 10 V). Positioning of detectors In warehouse passages is presence detection at best with a special solution. Detector PD-22000 with Lens no. 17, mounted in that end of the passage where one most often enter. PD-2200 should be mounted in the ceiling, on a suspended fitting at an angel of 40° to the vertical line. One PD-2200 with lens no. 17 can manage passages up to 50 meters in length. Individual fields in the lens system can be screened off so that fields do not reach areas where no detection is to take place, e.g. transverse passages. It is a good idea to carry out practical tests before the final design is implemented! Control system When warehouse passages are periodically used very frequently, i.e. when there are a lot of transits, installation of dynamic lighting control must be selected. This means fittings with dimmable HF operating devices, presence detection and level selectors. |

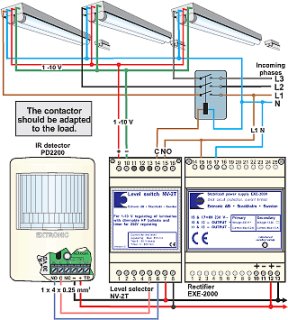

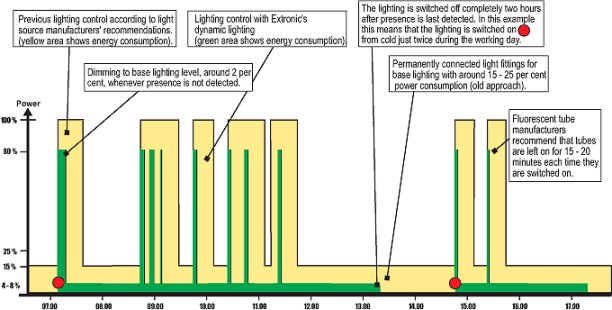

Dynamic lighting control provides the following function:

In the event of presence the lighting is switched on to approx. 80 per cent. One minute after the presence has ceased the lighting is reduced to approx. 2 per cent. In the event of entry into warehouse passages the lighting is immediately increased to 80 per cent again. After two hours without any presence the lighting is completely switched off to eliminate no-load losses. NV-2T level selector is also available with DSI control (NV-2T DSI). The most important advantages attained using Dynamic Control are as follows:

Installation of the detectors should use the simplest possible cable, e.g. EKKX 1 x 4 x 0.25 mm2. The same power supply can be used in up to 10 warehouse passages, depending on line lengths and positioning. |

||||||||||||||||||||||

|

|||||||||||||||||||||||

|

Information for current budget

|

||||||||||||||||||||||

|

|||||||||||||||||||||||

| Dynamic lighting control with NV-2T in warehouse aisle

The diagram shows the energy consumption in a warehouse aisle over one day. The yellow area shows the energy consumption with lighting control according to the light source manufacturer’s recommendations. The dynamic system adapts the lighting depending on how the warehouse is used, and in aisles that are unused the lighting remains switched off completely. |

|||||||||||||||||||||||

|

|||||||||||||||||||||||